We invest significant resources in providing fast and reliable preform and bottle proofing services, allowing our customers to quickly check the aesthetics and functionality of their packaging.

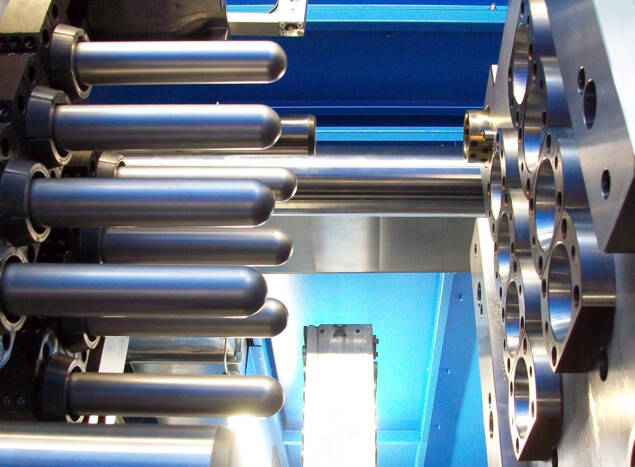

Our team of experts is at your service during the preform and bottle production process to assist you in the design of your sample bottles. In terms of pilot machines, we have 16 machines covering all preform and bottle production technology platforms (preform production systems, linear and rotary blow molders and one-step machines).

Injection molding experts

Our team of process technicians has extensive experience in preform development and can design a preform with a specific design based on the bottle shape required by the customer, or find the best preform currently available on the market. At the same time, we also test PET and other materials, including additives, masterbatches and special resins

Blowing bottle expert

We are able to develop and produce samples for a wide variety of containers and applications:

- Standard bottles and special containers;

- Bottles of various capacities, from 50 ml to 30 liters;

- Suitable for a wide range of applications, from water to soft drinks, from food to detergents, cosmetics and pharmaceuticals, including chemical products;

We can carry out both internal acceptance testing and online testing of bottle samples at the customer's site.

For every container we develop, we consider not only the technical aspects, but also economy, flexibility, security and sustainability.